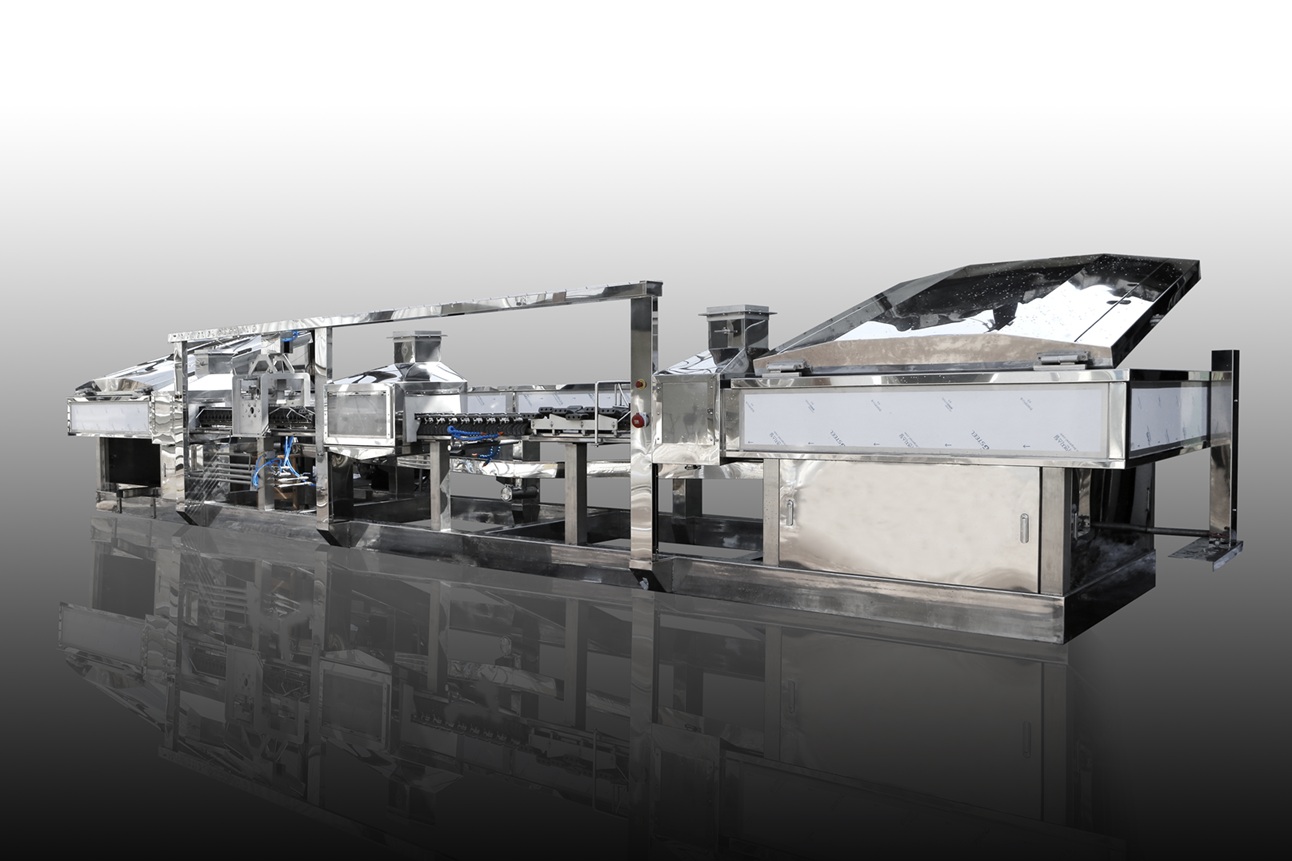

JOONGWON ENGINEERING provides total solutions for surimi and fish cake production lines, from customized design to installation and maintenance.

Four Reasons Global Clients Choose JOONGWON ENGINEERING

Growing alongside Korea’s surimi and fish cake industry, we deeply understand real production environments.

Decades of expertise in designing and manufacturing specialized food processing equipment.

Tailored engineering solutions optimized for each client’s process, space, and capacity.

Rapid on-site support by experienced engineers to minimize production downtime.

End-to-end solutions covering the entire food production process

Process analysis and optimized engineering drawings

Precision fabrication with safety and hygiene in mind

Seamless integration of forming, cooling, conveying, and cutting

On-site optimization and stable initial operation

Inspection and improvement for long-term stable operation

Core equipment powered by JOONGWON’s engineering expertise

High-speed cutting and mixing system designed to finely emulsify raw materials. Ensures uniform texture, stable protein extraction, and consistent product quality.

Delivers precise and stable transfer of processed materials to the next stage. Optimized to minimize air intake and maintain continuous, hygienic flow.

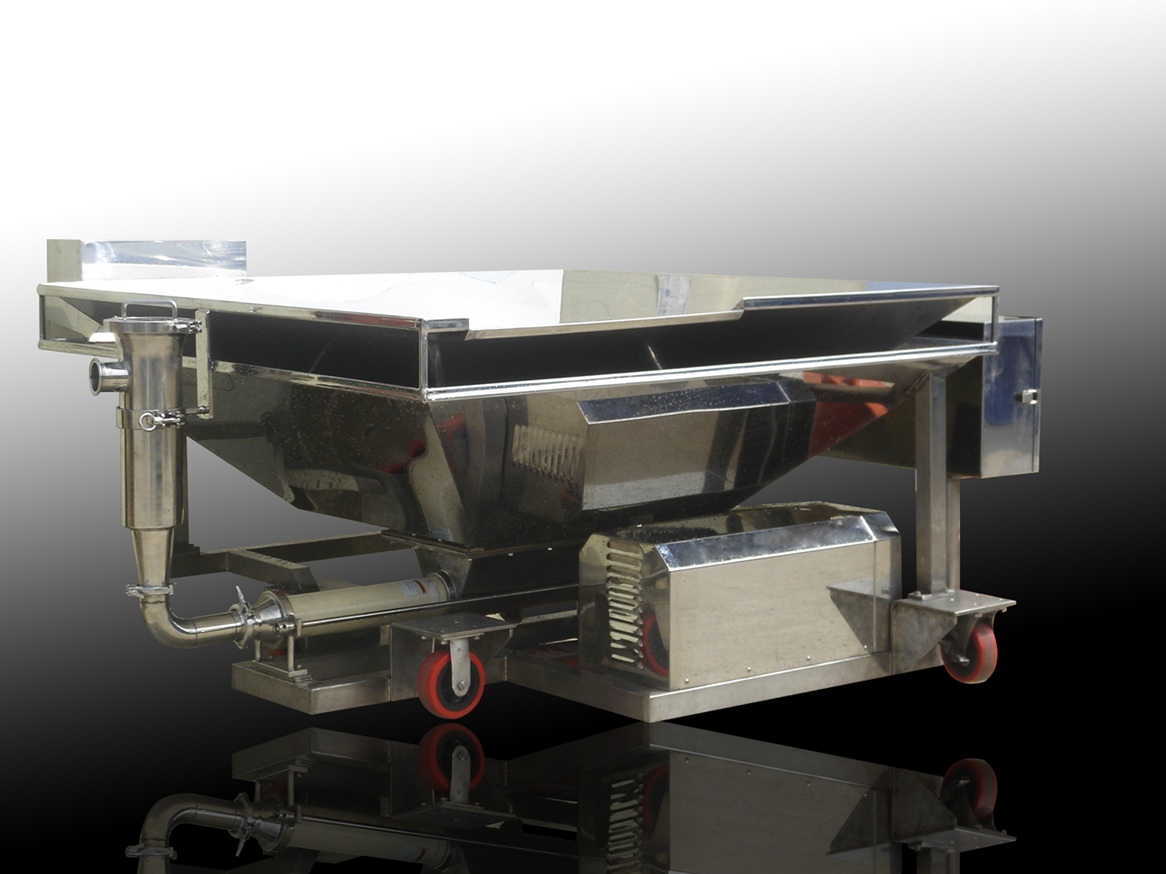

Evenly mixes and feeds paste into the nozzle without air pockets. Designed to improve molding accuracy and product consistency during forming.

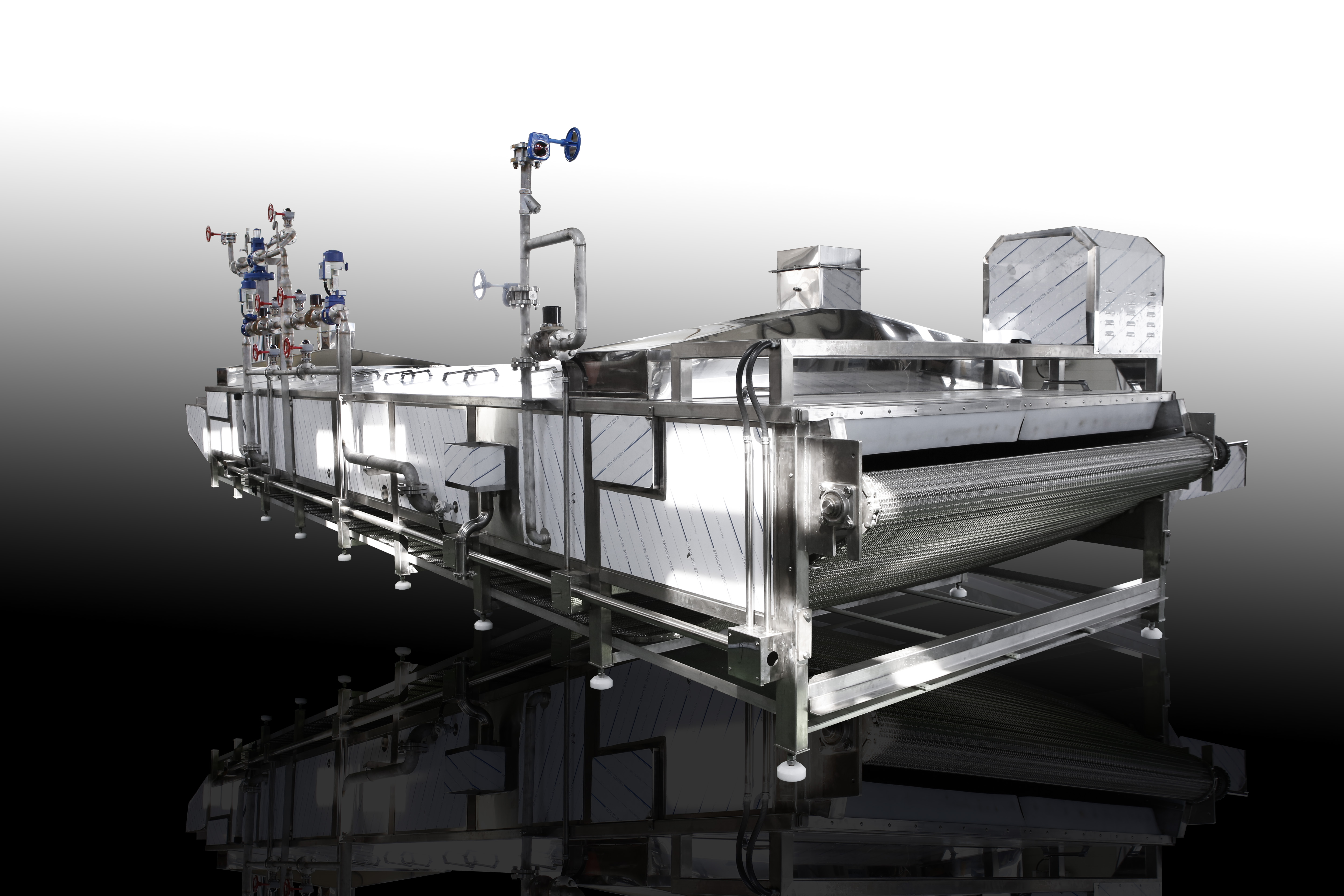

Sterilizes vacuum-packed products through controlled boiling and cooling processes. Ensures food safety, shelf-life stability, and uniform heat treatment.

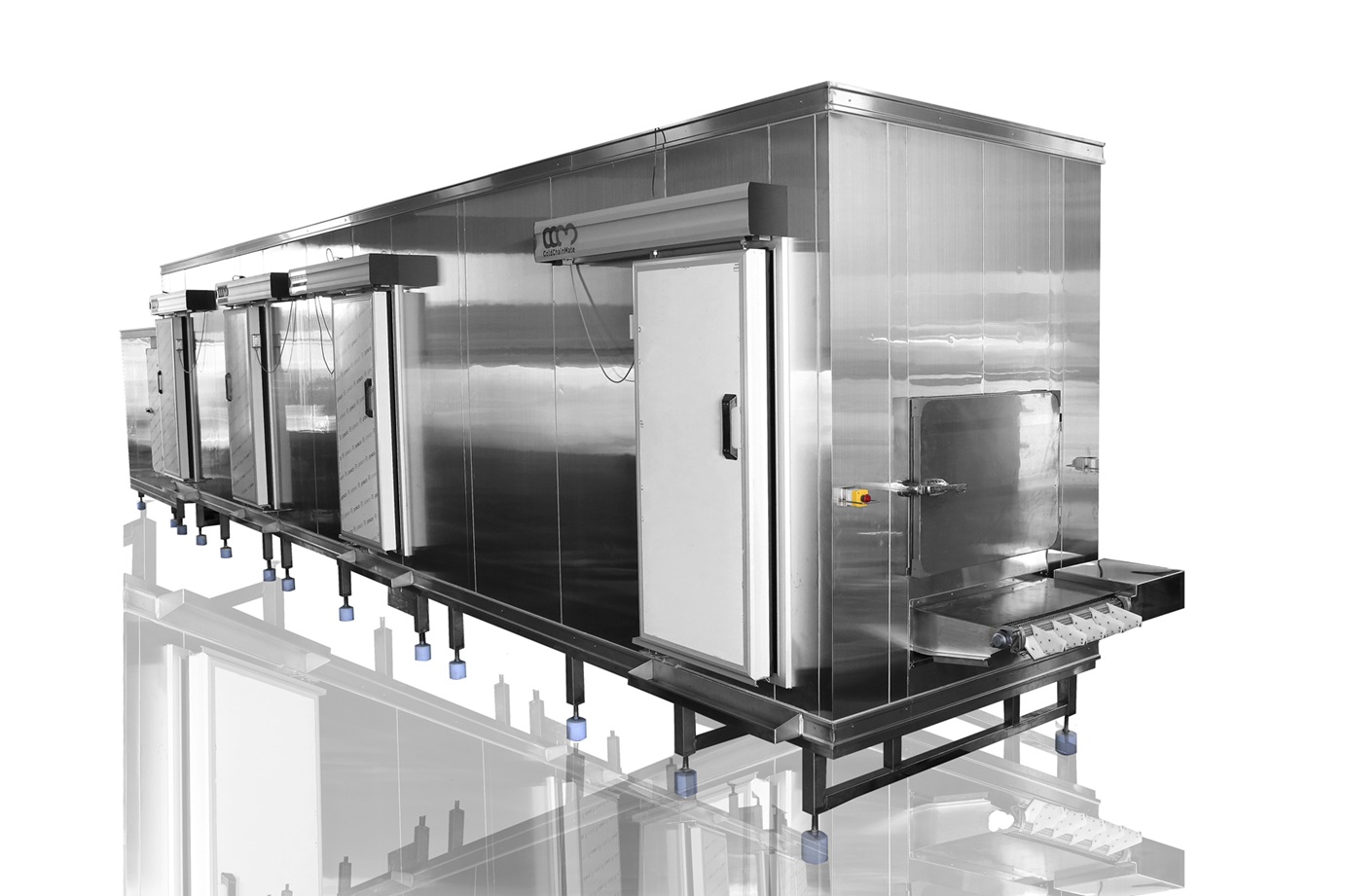

Rapidly cools heated products to suppress microbial growth. Maintains freshness, texture, and overall product quality after cooking.

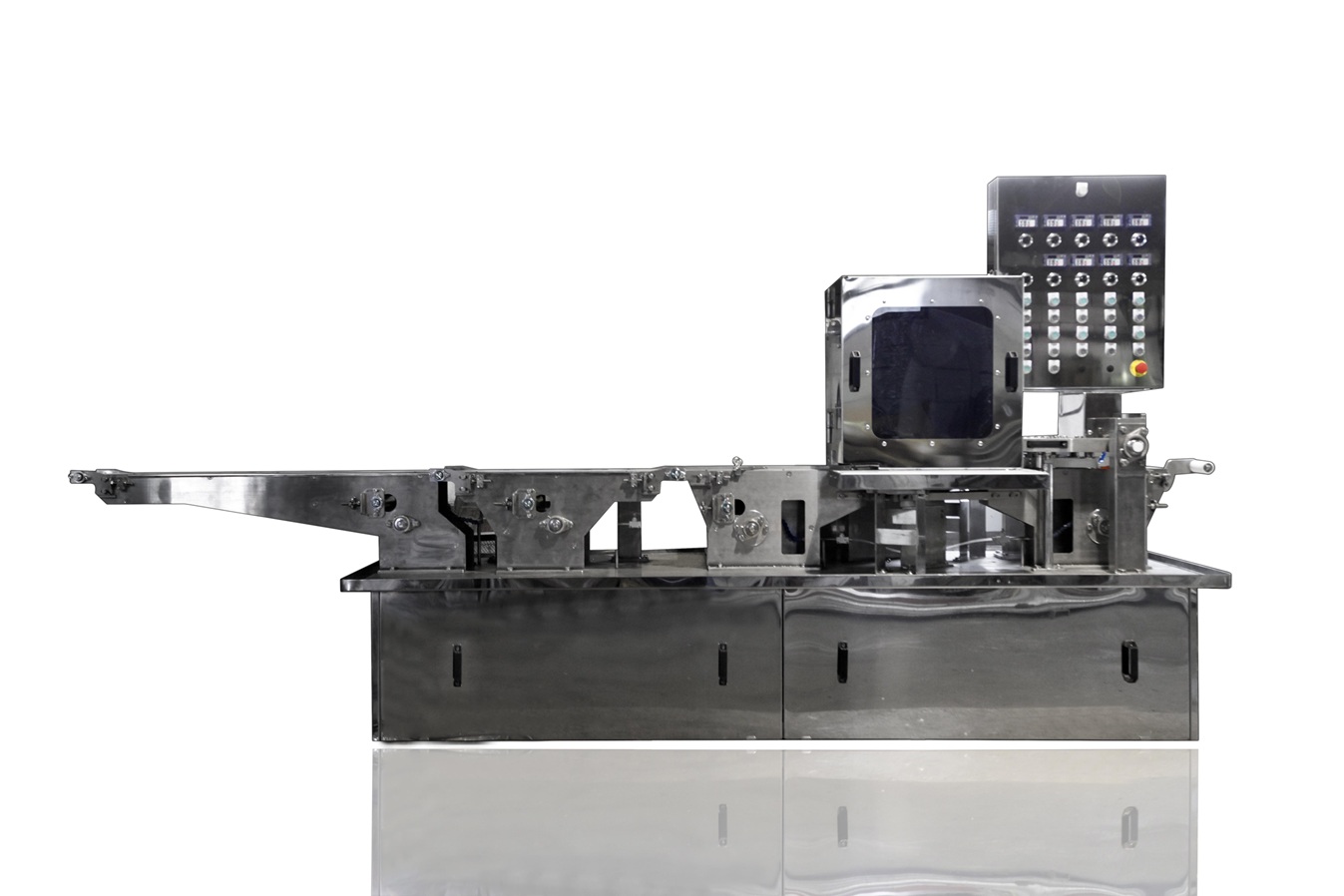

Versatile automatic filling system capable of producing various surimi products. Different product shapes are achieved simply by changing molds.

Steam-heats products inside a rotating drum to produce high-quality sheets. Provides uniform cooking and supports a wide range of sheet-based surimi products.

Cuts packaged products into clean, uniform portions with high precision. Designed for stable operation and consistent cutting performance.

Slits cooled surimi sheets into fine strands and applies controlled pressure for bundling. Creates stable, visually uniform crab stick structures.

Certified technologies supporting our engineering reliability

JOONGWON ENGINEERING continuously invests in R&D to deliver more efficient and hygienic automated production systems.

Trusted production line partner for leading food manufacturers worldwide